Types of Capacitor

Capacitors are widely used in electronics or electrical circuits, making them one of the leading technology pieces. Since they are used in most electronic devices, they are available in different sizes and types depending on various factors. Each type of capacitor has its purpose, features, advantages, and disadvantages.

In this article, we are discussing different types of capacitors that are in widespread use in manufactured electronic circuits nowadays. Before discussing the different capacitor types, let us first briefly overview the capacitor and other essential factors.

What is a Capacitor?

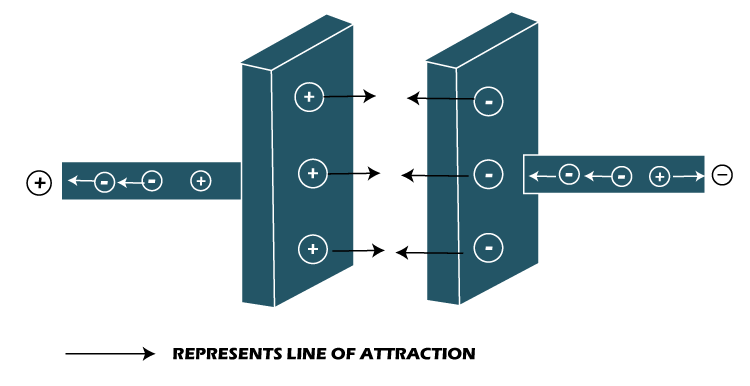

As the name suggests, capacitors refer to the idea of ‘capacity’, which means ‘ability to hold something’. The primary function of the capacitor is to hold the electric charge. In other words, a capacitor refers to a passive component that primarily holds the electrical energy. In terms of structure, a capacitor is made up of two conductive plates separated by a dielectric material. The dielectric material used between the conductive plates is also in the form of plates, which helps accumulate electric charges.

When a voltage is applied across the capacitor’s conductive plates, the current flow between the plates begins. One plate is positively charged due to lack of electrons, while the other is charged negatively due to excess of electrons. Since the plates have opposite charges, the opposite charges of the plates attract each other. Because there is an insulator between the two plates, the charges do not move from one side to the other and remain in a state of mutual attraction when the capacitor is idle. This is how capacitors hold the charges.

Capacitance

Capacitance is defined as the ratio between electric charge and voltage for a capacitor. The mathematical expression of capacitance is as follows:

Where,

C denotes the capacitance (in farad)

Q denotes the electric charge (in coulombs)

V denotes the electric voltage applied between the plates (in volts)

Types of Capacitor

There are many ranges of capacitor types with unique functionality and applications. They can range in size from very small to very large, depending on the requirements. For example, small capacitors are commonly used in small devices, such as radio circuits. Besides, large capacitors are best suited for smoothing circuits found in large electronic devices such as machinery.

When differentiating between capacitor types, the main factor is the dielectric used between the particular capacitor plates. The dielectric material is loaded between the plates to make the capacitors especially useful for specific purposes. This is what sets one capacitor apart from the others.

Regardless of the material used as a dielectric, each capacitor has its unique functions and plays a vital role in electronic circuits. Let us briefly introduce some of the most common and widely used capacitors:

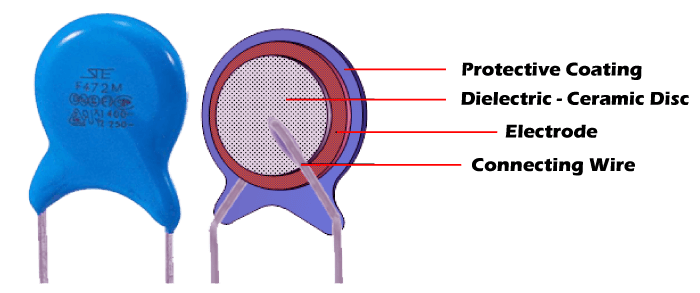

Ceramic Capacitors

Ceramic capacitors are the most widely used type among all capacitors. The name gives an idea that the word ceramic is derived from something used in a capacitor. Typically, these capacitors use ceramic material as a dielectric. Ceramic material is one of the first materials that was used as an insulator when making capacitors. Ceramic capacitors are usually made using small ceramic discs or porcelain discs. The discs are coated on both sides with silver before joining together to form a working capacitor. This is why they are also known as disk capacitors.

Ceramic capacitors are easy to develop with high and low capacitances by changing the disc’s thickness. Moreover, these capacitors are non-polarized and can therefore be used in circuits from both directions. Although the durability of ceramics is not so good, these capacitors work efficiently without defects. Besides, ceramics are not expensive and are available in different dielectric types.

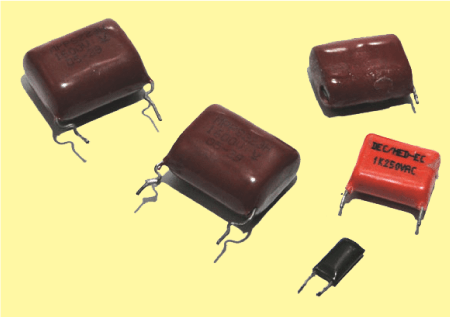

Film Capacitors

In terms of availability, film capacitors are the most common and readily available type of capacitors. These capacitors are built using thin plastic, often using plastics such as polyester and mylar. The dielectric properties usually vary according to the kind of plastic film. These capacitors are not polarized, and therefore, they are suitable only for AC voltage applications. Film capacitors are available in a variety of case styles or shapes, such as epoxy case (round and rectangular shape), wrap and fill (round and oval shape), and metal hermetically sealed case (round and rectangular sealed shape).

These capacitors are also called ‘plastic capacitors’ when film capacitors contain dielectrics such as polystyrene, Teflon, and polycarbonate. Electrodes of film capacitors are typically made using zinc or aluminum. Besides, these capacitors are cheap and come with a durable shelf life.

Power Film Capacitors

Power film capacitors are almost identical to regular film capacitors in structure, construction materials, and techniques. However, these capacitors use polypropylene film as a dielectric.

Electrolytic Capacitors

When high capacitance values are required to be obtained, electrolytic capacitors are preferred over other types of capacitors. An electrolyte refers to a liquid or a gel that contains a high amount of ions. The thin metal film layer is used for one conductive plate, and, for another plate, a semi-liquid electrolyte solution is used in liquid or jelly form. The distance between the two plates is kept very small. Additionally, the dielectric plate comprises a thin layer of oxide, typically less than ten microns.

Most of these capacitors are polarized. Therefore, electrolytic capacitors must be connected very carefully. If they are connected in the wrong way, such as positive to positive and negative to negative, this can cause a permanent loss of these capacitors. This is why electrolytic capacitors come with clearly marked signs of positive and negative terminals. Besides, these capacitors are mainly used in DC power supplies because of their large capacitance characteristic.

These capacitors are further subdivided into three other essential capacitor types, such as:

- Aluminum Electrolytic Capacitors: These are capacitors that use aluminum oxide as a dielectric. The oil is filled in these types of capacitors, which act as electrolytes. In these capacitors, conductive plates are made using chemically-etched aluminum foil. The etching technique helps create an aluminum porous like a sponge, which further achieves high surface area and high capacitance. Aluminum electrolytic capacitors are typically available in metal cans and surrounded by the thin plastic sheet. Voltage and capacitance ratings are written on these capacitors. Additionally, they may have a white-colored band in the side areas to indicate the cathode.

- Tantalum Electrolytic Capacitors: These are capacitors that use tantalum pentoxide as a dielectric. In these capacitors, the dielectric is surrounded by a conductive cathode. Besides, they use tantalum metal as the anode. The tantalum helps form a thin dielectric layer, which further helps obtain a higher capacitance value per volume and frequency. Furthermore, these capacitors are smaller than aluminum electrolytic capacitors and are known to have better stability over time.

- Niobium Electrolytic Capacitors: These are capacitors in which the electrolyte is a solid material made of niobium oxide. Also, these capacitors use niobium pentoxide as the dielectric. Niobium electrolytic capacitors typically have a minimal amount of internal resistance for a particular capacitance. These are somewhat less immune to overvoltage than other capacitors. Besides, these capacitors may go kaput with a hefty amount of nasty black smoke without giving any critical warning.

Supercapacitors

Supercapacitors are the type of capacitor that can hold a considerable amount of electric charge. They are polar devices and must be connected correctly in the circuit. These capacitors are also known as ultracapacitors and double-layer capacitors.

Supercapacitors typically use two different mechanics to hold electrical energy instead of the conventional dielectric. These mechanics include double-layer capacitance and pseudocapacitance. In particular, double-layer capacitance is called electrostatic in origin. Besides, pseudocapacitance is electrochemical. The fast charging and discharging feature of supercapacitors are very beneficial for many applications and may even replace the battery’s use.

Special Purpose Capacitors

Special purpose capacitors are developed to achieve any unique advantage in electric circuits. These are commonly used in AC power (typically up to 660 V AC), such as UPS and CVT systems. It is essential to carefully choose these capacitors because incorrect selection can damage the entire circuit or capacitor’s life.

It has also been suggested to use these capacitors by using a reasonable capacitor value through voltage-current variation with life expectancy and matching the exact application. These capacitors are robust, durable, shockproof, ambient, and dimensionally accurate.

Apart from the types mentioned above of capacitors, there are many more types, including polymer capacitors, silver mica capacitors, glass capacitors, silicon capacitors, air-gap capacitors, vacuum capacitors, pseudocapacitors, hybrid capacitors, etc.

Classification of Capacitor

Due to the widespread use of capacitors, there are several variations to classify capacitors. However, we can classify them into the following three categories:

- Polar and Non-polar Capacitors

- Leaded and Surface Mount Capacitors

- Variable and Fixed Capacitors

Polar and Non-polar Capacitors

One of the primary classifications of capacitors is based on whether they are polarized.

A polarized capacitor refers to the type of capacitor in which the voltage is applied at an absolute polarity. This type of capacitor is mainly used to obtain high amounts of capacitive density. These are often called aluminum electrolytic and tantalum. All such capacitors are characterized with positive and negative terminals and should only be used in a forward-biased (voltage biased in their direction). Besides, reverse bypassing can damage these capacitors or wreck them. These capacitors support coupling and decoupling and, therefore, must have a permanent DC voltage applied to them. However, they pass only AC components.

Other forms of the capacitor are classified as non-polar or non-polarized capacitors. These capacitors are considered to be better than polarized capacitors as there is no need for polarity, and hence they can be connected in any way to electrical circuits. This means that non-polarized circuits are not destroyed when connected to reverse voltages or used in pure AC circuits. Besides, these capacitors can also be used in DC circuits because these capacitors have no positive and negative ends. Non-polarized capacitors have high frequency and low leakage current. Capacitors such as ceramic, film, mica, and many others are non-polar capacitors.

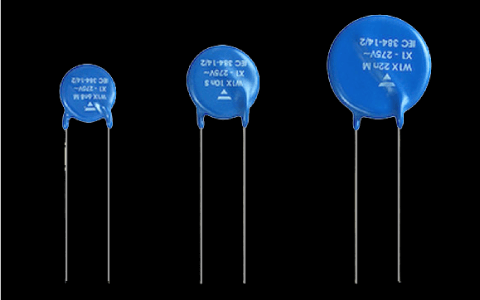

Leaded and Surface Mount Capacitors

Capacitors can also be distinguished as lead and surface mounts. Typically, most capacitors are available as virtually leaded versions. Some such capacitors are ceramic, electrolytic, mica, film, and many other specific types. Besides, ceramic, electrolytic, and tantalum are also types of surface mount capacitors. Almost every surface mount capacitor can cope with high-temperature soldering.

Variable and Fixed Capacitors

The final and most popular type of capacitor classification depends on whether they were fixed or variable.

Fixed capacitors are available in a wide range and are preferred in electric circuits. They are in the majority and do not support any form of adjustment. This type of capacitor is usually classified based on the dielectric used within the capacitor. The dielectric material and its volume generally control these capacitors’ basic properties, making them ceramics, electrolytic, mica, film, and many other capacitors.

Variable capacitors are adjustable and are mostly used where the value of the capacitor needs to be changed. These capacitors usually have a control knob that helps adjust the capacitor value. For example, a radio usually comes with a control knob that allows tuning the radio frequency. These capacitors have a relatively low value; however, their maximum values can be up to 1000pF. Besides, some variable capacitors come with a screw adjustment, called a preset. These capacitors must be configured during setup, test, calibration, etc. These have not been developed to accommodate real-time usage.